The outer heath is of PVC compound confirming to the requiremnets of type 6 compund of IS:5831-1970.

The colour of outer sheath is genereally Black.

CABLE CODE:

The following code is used for easy identification of the cables.

META PLAST 1.1KV SINGLE CORE, ALUMINIUM CONDUCTOR, PVC INSULATED

UNARMOURED & PVC SHEATHED CABLES AS PER IS:1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of Insualtion |

Nominal thickness of Outer Sheath |

Approx overall diameter |

Approx weight of cable |

Max. Dc conductor resistance at 200 C |

CURRENT RATINGS |

Direct in Ground |

In Duct |

In Air |

2 cables Amps |

3 cables Amps |

2 cables Amps |

3 cables Amps |

2 cables Amps |

3 cables Amps |

Sq.mm |

mm |

mm |

mm |

kg / km |

Ohm / km |

1 x 1.5 |

1.1 |

1.8 |

7.4 |

63 |

19.7 |

21 |

17 |

19 |

17 |

18 |

15 |

1 x 2.5* |

1.2 |

1.8 |

8.0 |

74 |

11.8 |

28 |

24 |

25 |

24 |

25 |

21 |

1 x 4* |

1.3 |

1.8 |

8.7 |

88 |

7.39 |

36 |

31 |

33 |

30 |

32 |

27 |

1 x 6* |

1.3 |

1.8 |

9.2 |

101 |

4.91 |

44 |

39 |

42 |

37 |

41 |

35 |

1 x 10* |

1.3 |

1.8 |

10.0 |

122 |

2.94 |

54 |

51 |

56 |

51 |

56 |

47 |

1 x 16 |

1.3 |

1.8 |

11.5 |

161 |

1.87 |

75 |

66 |

71 |

65 |

72 |

64 |

1 x 25 |

1.5 |

1.8 |

12.9 |

209 |

1.18 |

97 |

86 |

93 |

84 |

99 |

84 |

1 x 35 |

1.5 |

1.8 |

14.0 |

251 |

0.851 |

120 |

100 |

110 |

100 |

120 |

105 |

1 x 50 |

1.5 |

1.8 |

15.2 |

301 |

0.628 |

145 |

120 |

130 |

115 |

150 |

130 |

1 x 70 |

1.5 |

1.8 |

17.0 |

386 |

0.435 |

170 |

140 |

155 |

135 |

185 |

155 |

1 x 95 |

1.6 |

2.0 |

19.4 |

510 |

0.313 |

205 |

175 |

180 |

155 |

215 |

190 |

1 x 120 |

1.6 |

2.0 |

20.9 |

601 |

0.248 |

230 |

195 |

200 |

170 |

240 |

220 |

1 x 150 |

1.8 |

2.0 |

22.8 |

722 |

0.202 |

265 |

220 |

220 |

190 |

270 |

250 |

1 x 185 |

2.0 |

2.0 |

25.0 |

871 |

0.161 |

300 |

240 |

240 |

210 |

305 |

290 |

1 x 240 |

2.2 |

2.0 |

27.9 |

1098 |

0.122 |

335 |

270 |

270 |

225 |

350 |

335 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

META PLAST 1.1 KV TWIN CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHED

UNARMOURED & PVC SHEATHED CABLES AS PER IS: 1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of Insualtion |

Minium thickness of Inner Sheath |

Normal thickness Outer Sheath |

Approx overallt of cable |

Approx weight of cable |

Max. Dc conductor resistance at 200 C |

CURRENT RATINGS |

Direct in Ground |

In Duct |

In Air |

Amps |

Amps |

Amps |

Sq.mm |

Mm |

Mm |

Mm |

Mm |

kg / km |

Ohm / km |

2 x 1.5 |

0.8 |

0.3 |

1.8 |

10.4 |

135 |

20.0 |

18 |

16 |

16 |

2 x 2.5* |

0.9 |

0.3 |

1.8 |

11.6 |

194 |

12.0 |

25 |

21 |

21 |

2 x 4* |

1.0 |

0.3 |

1.8 |

13.0 |

247 |

7.54 |

32 |

27 |

27 |

2 x 6* |

1.0 |

0.3 |

1.8 |

14.0 |

258 |

5.01 |

40 |

34 |

35 |

2 x 10* |

1.0 |

0.3 |

1.8 |

15.6 |

351 |

3.00 |

55 |

45 |

47 |

2 x 16 |

1.0 |

0.3 |

1.8 |

16.5 |

364 |

1.91 |

70 |

58 |

59 |

2 x 25 |

1.2 |

0.3 |

2.0 |

19.4 |

480 |

1.20 |

90 |

76 |

78 |

2 x 35 |

1.2 |

0.3 |

2.0 |

21.0 |

600 |

0.868 |

110 |

92 |

99 |

2 x 50 |

1.4 |

0.3 |

2.0 |

23.7 |

750 |

0.641 |

135 |

115 |

125 |

2 x 70 |

1.4 |

0.3 |

2.0 |

26.3 |

900 |

0.443 |

160 |

140 |

150 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

META PLAST 1.1 KV THREE CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHED UNARMOURED & PVC

SHEATHED CABLES AS PER IS:1554 (PART I) AMENDED UPTO DATE

| Nominal cross sectional area |

Nominal thickness of Insualtion |

Minium thickness of Inner Sheath |

Normal thickness Outer Sheath |

Approx overallt of cable |

Approx weight of cable |

Max. Dc conductor resistance at 200 C |

CURRENT RATINGS |

Direct in Ground |

In Duct |

In Air |

Amps |

Amps |

Amps |

Sq.mm |

Mm |

Mm |

Mm |

Mm |

kg / km |

Ohm / km |

3 x 1.5 |

0.8 |

0.3 |

1.8 |

10.9 |

160 |

20.0 |

16 |

14 |

13 |

3 x 2.5* |

0.9 |

0.3 |

1.8 |

12.2 |

221 |

12.0 |

21 |

18 |

18 |

3 x 4* |

1.0 |

0.3 |

1.8 |

13.7 |

242 |

7.54 |

28 |

23 |

23 |

3 x 6* |

1.0 |

0.3 |

1.8 |

14.8 |

320 |

5.01 |

35 |

30 |

30 |

3 x 10* |

1.0 |

0.3 |

1.8 |

16.5 |

366 |

3.00 |

46 |

39 |

40 |

3 x 16 |

1.0 |

0.3 |

1.8 |

17.8 |

436 |

1.91 |

60 |

50 |

51 |

3 x 25 |

1.2 |

0.3 |

2.0 |

21.2 |

630 |

1.20 |

76 |

63 |

70 |

3 x 35 |

1.2 |

0.3 |

2.0 |

23.1 |

706 |

0.868 |

92 |

77 |

86 |

3 x 50 |

1.4 |

0.3 |

2.0 |

26.1 |

903 |

0.641 |

110 |

95 |

105 |

3 x 70 |

1.4 |

0.3 |

2.2 |

29.7 |

1200 |

0.443 |

135 |

115 |

130 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

META PLAST 1.1 KV 31/2 CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHED UNARMOURED & PVC SHEATHED

CABLES CONFORMING TO IS :1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of insulation |

Minimum thickness of inner sheath |

Minimum thickness of Outer sheath |

Approx overall diameter |

Approx weight of cable |

Max. DC conductor resistance at 20°C |

CURRENT RATINGS |

Sq.mm |

Neutral

Sq.mm |

Main mm |

Neutral

Smm |

Mm |

Mm |

Mm |

Kg/ Km |

Main Ohm / km |

Neutral Ohm / km |

Direct in Ground Amps |

In Ducts Amps |

In Air Amps |

31/2 x 35 |

16 |

1.2 |

1.0 |

0.3 |

2.0 |

23.9 |

702 |

1.20 |

1.91 |

76 |

63 |

70 |

31/2 x 25 |

16 |

1.2 |

1.0 |

0.3 |

2.0 |

26.2 |

800 |

0.868 |

1.91 |

92 |

77 |

86 |

31/2 x 50 |

25 |

1.4 |

1.2 |

0.3 |

2.2 |

29.5 |

1027 |

0.641 |

1.20 |

110 |

95 |

105 |

31/2 x 70 |

35 |

1.4 |

1.2 |

0.3 |

2.2 |

33.5 |

1550 |

0.443 |

0.868 |

135 |

115 |

130 |

META PLAST 1.1 KV FOUR CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHED UNARMOURED & PVC SHEATHED

CABLES AS PER IS :1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of Insualtion |

Minium thickness of Inner Sheath |

Normal thickness Outer Sheath |

Approx overallt of cable |

Approx weight of cable |

Max. Dc conductor resistance at 200 C |

CURRENT RATINGS |

Direct in Ground |

In Duct |

In Air |

Amps |

Amps |

Amps |

Sq.mm |

Mm |

Mm |

Mm |

Mm |

kg / km |

Ohm / km |

4 x 1.5 |

0.8 |

0.3 |

1.8 |

11.7 |

180 |

20.0 |

16 |

14 |

13 |

4 x 2.5* |

0.9 |

0.3 |

1.8 |

13.1 |

225 |

12.0 |

21 |

18 |

18 |

4 x 4* |

1.0 |

0.3 |

1.8 |

14.8 |

269 |

7.54 |

28 |

23 |

23 |

4 x 6* |

1.0 |

0.3 |

1.8 |

16.0 |

316 |

5.01 |

35 |

30 |

30 |

4 x 10* |

1.0 |

0.3 |

1.8 |

17.9 |

411 |

3.00 |

46 |

39 |

40 |

4 x 16 |

1.0 |

0.3 |

2.0 |

20.3 |

532 |

1.91 |

60 |

50 |

51 |

4 x 25 |

1.2 |

0.3 |

2.0 |

23.9 |

719 |

1.20 |

76 |

63 |

70 |

4 x 35 |

1.2 |

0.3 |

2.0 |

26.0 |

897 |

0.868 |

92 |

77 |

86 |

4 x 50 |

1.4 |

0.3 |

2.2 |

30.1 |

1189 |

0.641 |

110 |

95 |

105 |

4 x 70 |

1.4 |

0.4 |

2.2 |

33.9 |

1548 |

0.443 |

135 |

115 |

130 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

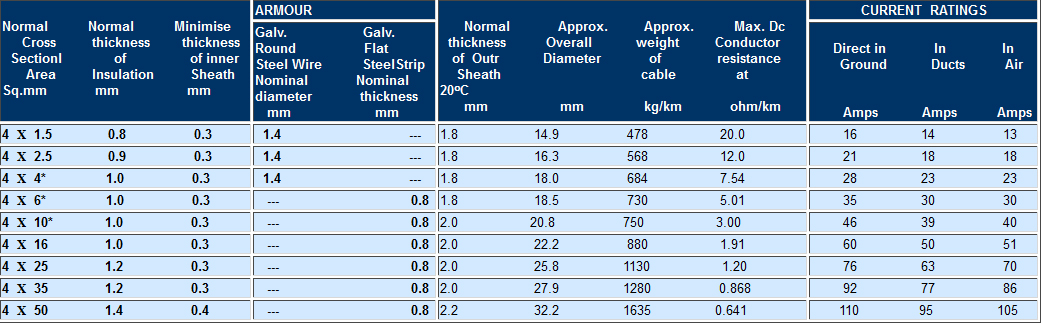

META PLAST 1.1KV TWIN CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHER ARMOURED & PVC SHEATHED

CABLES AS PER IS : 1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of Insulation |

Minimum thickness of Inner sheath |

ARMOUR |

Nominal thickness of Outer sheath |

Approx overall diameter |

Approx weight of cable |

Max Dc conductor resistance at 20°C |

CURRENT RATINGS |

|

Galv.Round Steel Wire Normal diameter |

Galv.Flat Steel Strip Normal thickness |

|

Direct in Ground |

In Ducts |

In Air |

Sq.mm |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/km |

Ohm/km |

Amps |

Amps |

Amps |

2 x 1.5 |

0.8 |

0.3 |

1.4 |

-- |

1.8 |

13.6 |

410 |

20.0 |

18 |

16 |

16 |

2 x 2.5* |

0.9 |

0.3 |

1.4 |

-- |

1.8 |

14.8 |

472 |

12.0 |

25 |

21 |

21 |

2 x 4* |

1.0 |

0.3 |

1.4 |

-- |

1.8 |

16.2 |

568 |

7.54 |

32 |

27 |

27 |

2 x 6* |

1.0 |

0.3 |

1.4 |

-- |

1.8 |

17.2 |

632 |

5.01 |

40 |

34 |

35 |

2 x 10* |

1.0 |

0.3 |

1.4 |

-- |

1.8 |

18.3 |

750 |

3.00 |

55 |

45 |

47 |

2 x 16 |

1.0 |

0.3 |

-- |

0.8 |

2.0 |

19.7 |

770 |

1.91 |

70 |

58 |

59 |

2 x 25 |

1.2 |

0.3 |

-- |

0.8 |

2.0 |

21.2 |

800 |

1.20 |

90 |

76 |

78 |

2 x 35 |

1.2 |

0.3 |

-- |

0.8 |

2.0 |

22.9 |

920 |

0.868 |

110 |

92 |

99 |

2 x 50 |

1.4 |

0.3 |

-- |

0.8 |

2.0 |

25.6 |

1042 |

0.641 |

135 |

115 |

125 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

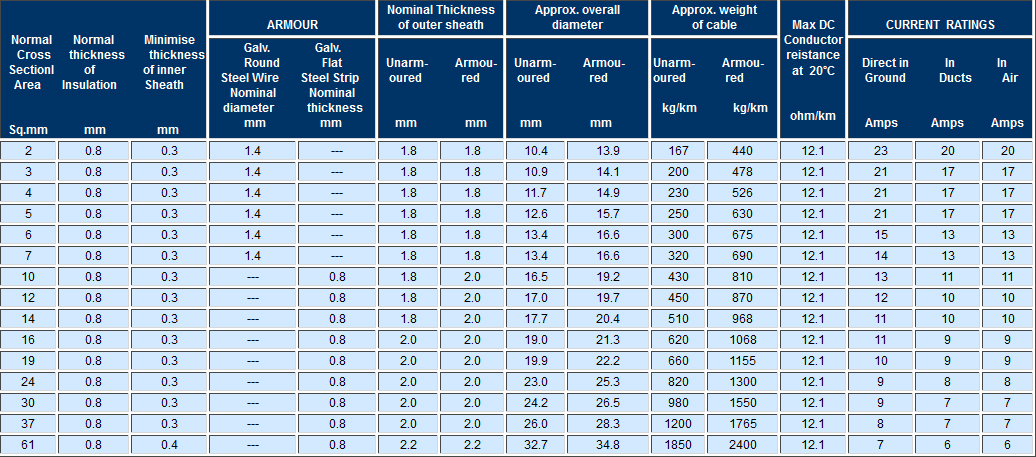

META PLAST 1.1KV THREE CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHER ARMOURED & PVC

SHEATHED CABLES AS PER IS : 1554 (PART I) AMENDED UPTO DATE

| Nominal cross sectional area |

Nominal thickness of Insulation |

Minimum thickness of Inner sheath |

ARMOUR |

Nominal thickness of Outer sheath |

Approx overall diameter |

Approx weight of cable |

Max Dc conductor resistance at 20°C |

CURRENT RATINGS |

Galv.Round Steel Wire Normal diameter |

Galv.Flat Steel Strip Normal thickness |

Direct in Ground |

In Ducts |

In Air |

Sq.mm |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/km |

Ohm/km |

Amps |

Amps |

Amps |

3 x 1.5 |

0.8 |

0.3 |

1.4 |

-- |

1.8 |

14.1 |

440 |

20.0 |

16 |

14 |

13 |

3 x 2.5* |

0.9 |

0.3 |

1.4 |

-- |

1.8 |

15.4 |

520 |

12.0 |

21 |

18 |

18 |

3 x 4* |

1.0 |

0.3 |

1.4 |

-- |

1.8 |

16.9 |

613 |

7.54 |

28 |

23 |

23 |

3 x 6* |

1.0 |

0.3 |

1.4 |

-- |

1.8 |

18.0 |

680 |

5.01 |

35 |

30 |

30 |

3 x 10* |

1.0 |

0.3 |

-- |

0.8 |

2.0 |

19.4 |

720 |

3.00 |

46 |

39 |

40 |

3 x 16 |

1.0 |

0.3 |

-- |

0.8 |

2.0 |

20.1 |

766 |

1.91 |

60 |

50 |

51 |

3 x 25 |

1.2 |

0.3 |

-- |

0.8 |

2.0 |

23.1 |

920 |

1.20 |

76 |

63 |

70 |

3 x 35 |

1.2 |

0.3 |

-- |

0.8 |

2.0 |

25.0 |

1047 |

0.868 |

92 |

77 |

86 |

3 x 50 |

1.4 |

0.3 |

-- |

0.8 |

2.0 |

28.0 |

1249 |

0.641 |

110 |

95 |

105 |

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

META PLAST 1.1KV 31/2 CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHER ARMOURED & PVC

SHEATHED CABLES AS PER IS : 1554 (PART I) AMENDED UPTO DATE

Nominal cross sectional area |

Nominal thickness of Insulation |

Minimum thickness of Inner sheath |

ARMOUR |

Nominal thickness of Outer sheath |

Approx diameter |

Approx weight of cable |

Max Dc conductor resistance at 20°C |

CURRENT RATINGS |

|

Galv.Flat Steel Strip |

|

Direct in Ground |

In Ducts |

In Air |

|

Main Sq.mm |

Neutral Sq.mm |

Main Sq.mm |

Neutral Sq.mm |

Mm |

Mm |

Mm |

Mm |

Kg/km |

Main

Ohm/km |

Neutral

Ohm/km |

Amps |

Amps |

Amps |

31/2 x 25 |

16 |

1.2 |

1.0 |

0.3 |

0.8 |

2.0 |

25.8 |

1048 |

1.20 |

1.91 |

76 |

63 |

70 |

31/2 x 35 |

16 |

1.2 |

1.0 |

0.3 |

0.8 |

2.0 |

28.1 |

1221 |

0.868 |

1.91 |

92 |

77 |

86 |

31/2 x 50 |

25 |

1.4 |

1.2 |

0.3 |

0.8 |

2.2 |

31.4 |

1529 |

0.641 |

1.20 |

100 |

95 |

105 |

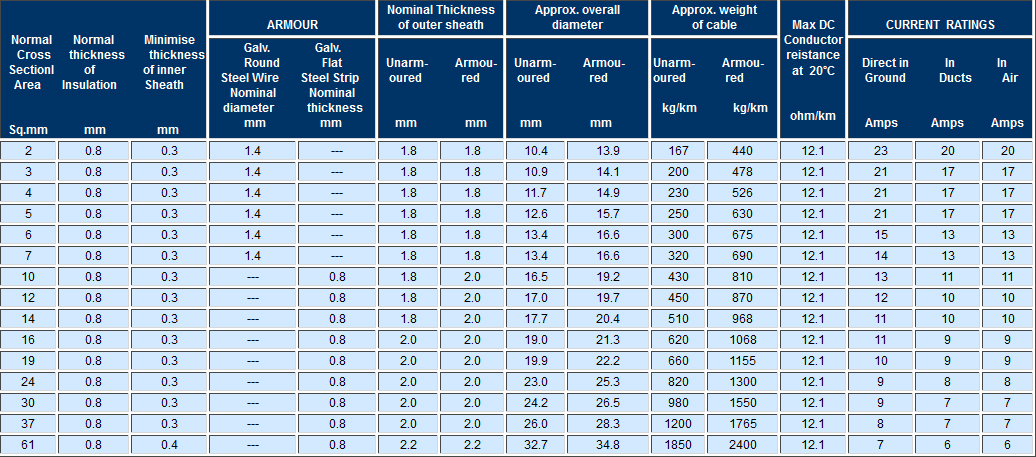

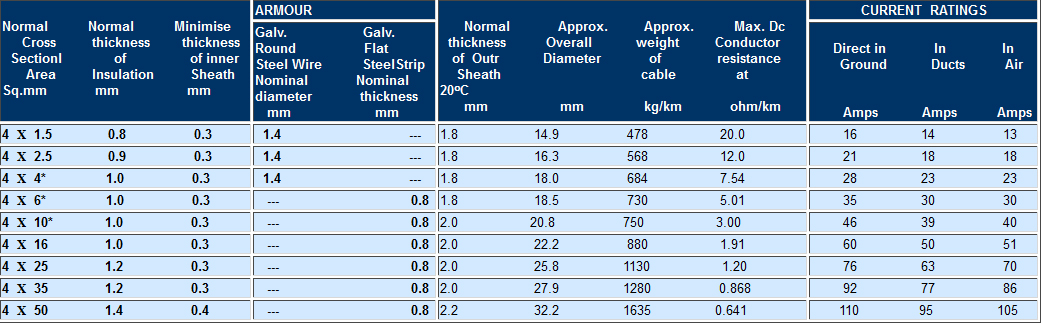

METAPLAST 1.1 KV FOUR CORE, ALUMINIUM CONDUCTOR, PVC INSULATED INNER SHEATHED ARMOURED PVC

SHEATHED CABLES AS PER IS :1554 (PART 1) AMENDED UPTO DATE

* If required, cables can be made with stranded conductor also. *Not covered in IS : 1554 (Part 1) 1976

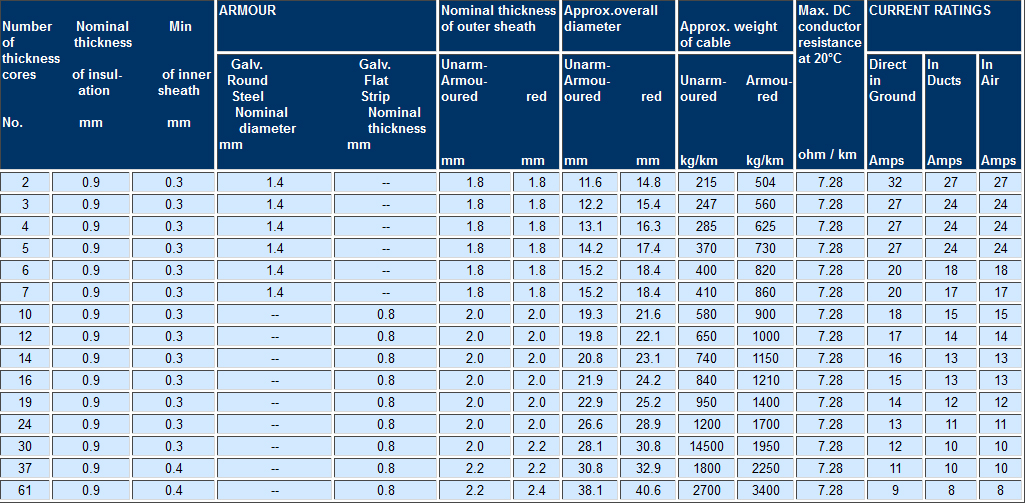

METAPLAST 1.1 KV ANNEALED HIGH CONDUCTIVITY SOLID COPPER CONDUCTOR 1.5 Sq. mm. PVCINSULATED INNER SHEED, ARMOURED / UNARMOURED &

PVC SHEATHED CONTROL CABLES AS PER IS :1554 (PART 1) AMENDED UPTO DATE